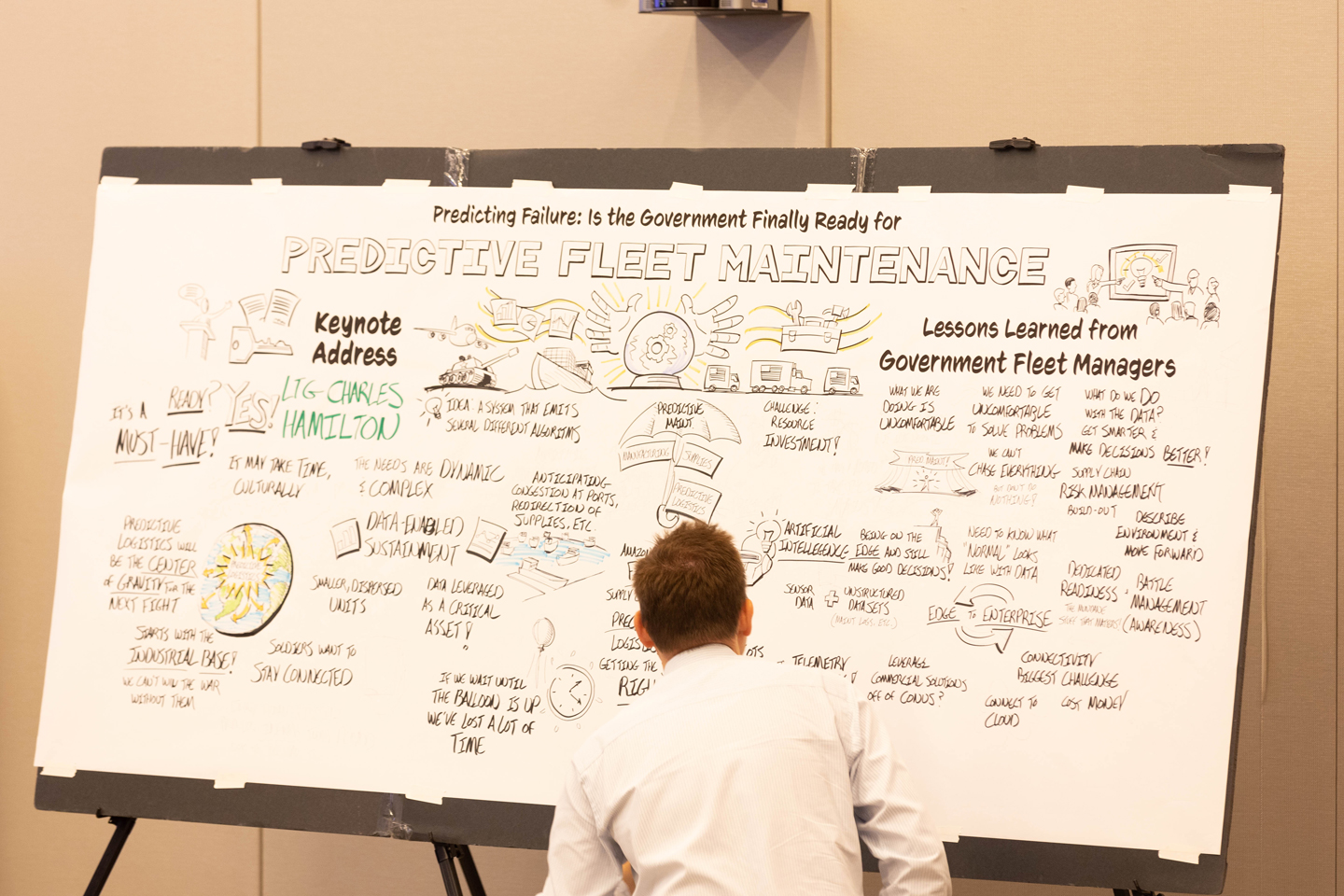

Predicting Failure: Is the Government Finally Ready for Predictive Fleet Maintenance?

Data & Analytics, Innovation at the Pace of Need®, Logistics, Predictive Analytics, Fleet PerformanceOn June 16th, LMI hosted a workshop that posed the question: Is the Government Finally Ready for Predictive Fleet Maintenance? The resounding answer? Yes!

Predictive maintenance is not a new concept, but it has been challenging for government organizations to operationalize at the enterprise level. Our workshop brought together experts from government, industry, and academia to identify the past obstacles to progress and propose solutions.

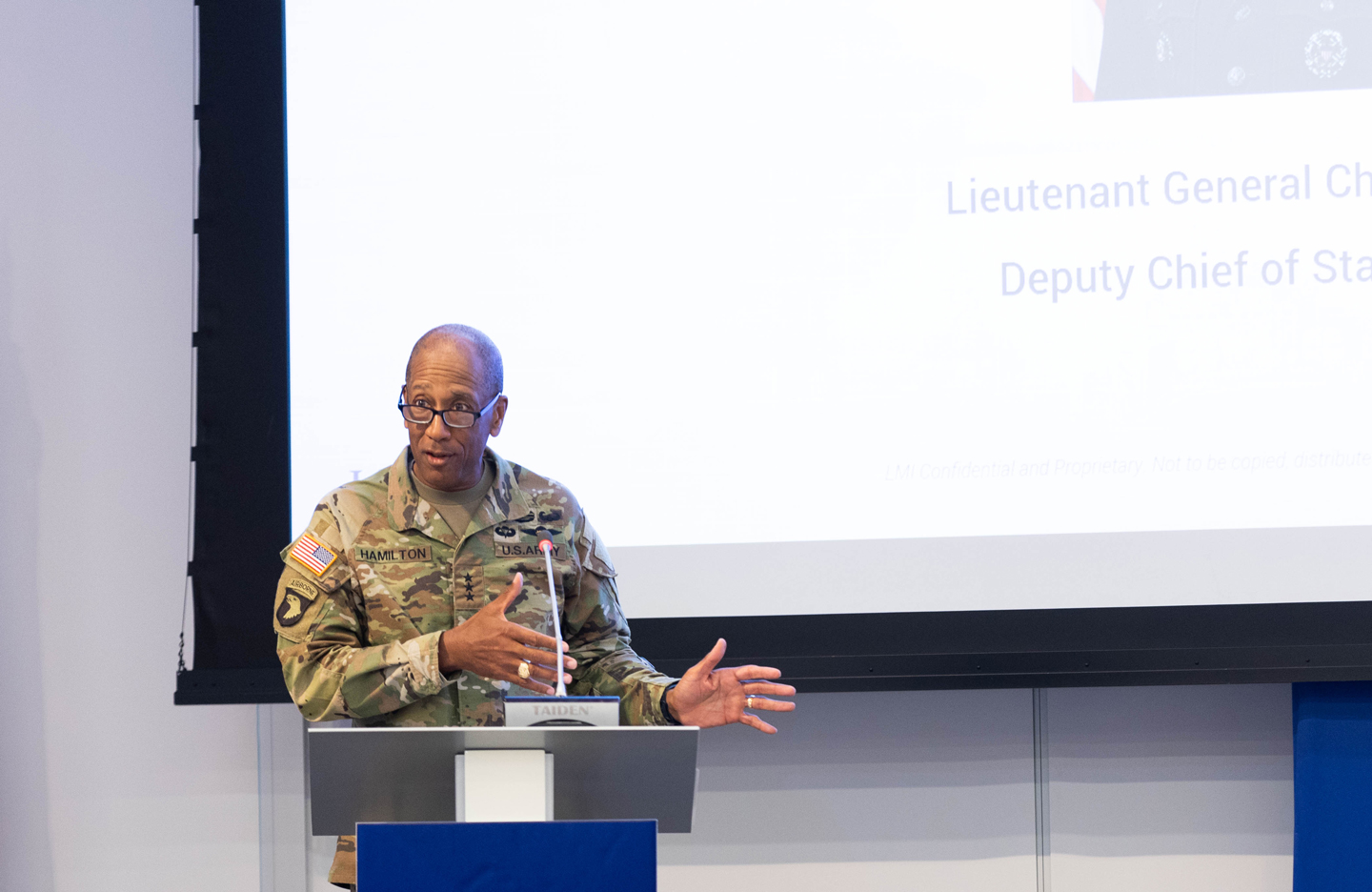

Keynote speaker, LTG Charles Hamilton, set the scene by discussing the broader concept of “Predictive Logistics” that encompasses not only maintenance but supply, manufacturing, and transportation. All these functions need to be data-driven and predictive to enable mission readiness in the future.

The members of our distinguished panel agreed and elaborated on many of LTG Hamilton’s themes. Ms. Leigh Method, DASD Logistics, argued that leaders and key stakeholders in government need to collaborate on solving the most pressing problems using the right data and must avoid pursuing ill-defined initiatives. Many workshop participants resonated with Ms. Method’s contention that one way to help drive this discipline is by connecting sustainment initiatives with the right acquisition approaches and supporting policies.

COL James Hartle, from US Air Force Headquarters, A4, argued that one of the most pressing problems he saw facing Air Force planners was how to supply forces in a contested environment, and that predictive maintenance was clearly part of the solution, especially when teamed with capabilities like autonomous resupply.

Stressing use cases like that, reasoned Jeff Banks from Penn State University’s Applied Research Laboratory, are what makes predictive maintenance in the government so different from industrial use cases. Data availability and network connectivity, among other obstacles, mean that commercial off-the-shelf solutions often can’t be successfully leveraged in the DOD, especially.

But our two industry panelists, Logan Jones from AI company SparkCognition and Andrew Givens from Amazon Web Services (AWS), gave cause for optimism, discussing how rapid advances in data acquisition and analytic technologies offer unique opportunities to deliver distributed and secure predictive analytics at the edge. During breakout sessions, participants discussed how implementation for predictive fleet maintenance faces similar challenges, no matter their mission. Most organizations face challenges with access to quality data, balancing relationships with original equipment manufacturers (OEMs), maneuverability within policies and procedures that do not change at the pace of need, and cultural change management. Our participants explored these topics in-depth and shared potential solutions and lessons learned from their own experiences.

So, what’s next?

If predictive maintenance, and predictive logistics more broadly, are the wave of the future, as our workshop participants all seemed to agree, then government and industry will have to work closely together to design solutions that can work with government people, policies, processes, and data environments. Government leaders who understand the potential of technology like artificial intelligence, machine learning, and digital twins need to seek out and collaborate, rather than work at arms-length, with industry partners that understand the unique context of government. We hope our workshop was a useful step in driving that forward.

-

LMI's Technology Accelerator

LMI Forge leverages agile methods to build scalable technologies and reusable solutions for our customers.

How We Innovate

Operating in an innovation ecosystem, we combine market-leading technical resources, strategic partnerships, and agile development capabilities to accelerate mission success.